Clutch Servo deeply integrates mechanical, hydraulic or pneumatic transmission technology, as well as advanced electronic control technology, to provide drivers with a smoother and easier clutch operation experience.

During driving, every time the driver taps the clutch pedal, this subtle movement is immediately captured by highly sensitive sensors. These sensors are like precise "tactile nerves" that can accurately sense the position changes of the pedal and the amount of force applied, and convert them into electrical signals, which are quickly transmitted to the vehicle's control unit - ECU (electronic control unit).

As the "brain" of the entire system, ECU immediately starts its built-in complex algorithms and programs after receiving the signal from the sensor to quickly analyze and process the signal. Based on the preset parameters and the driver's operating habits, ECU calculates the optimal power requirement and issues precise instructions to the servo mechanism.

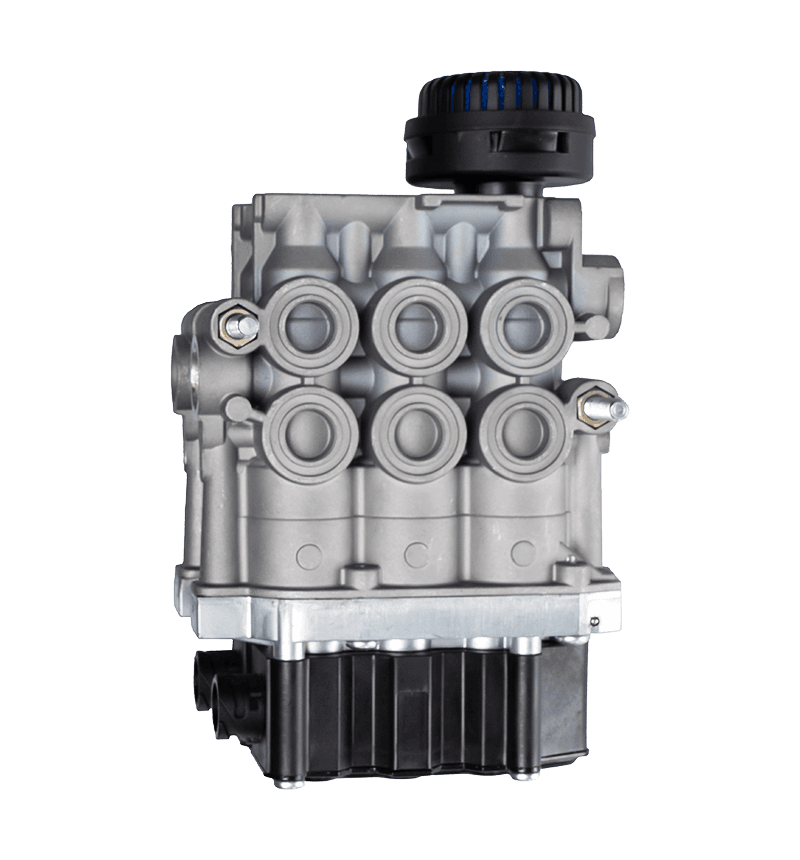

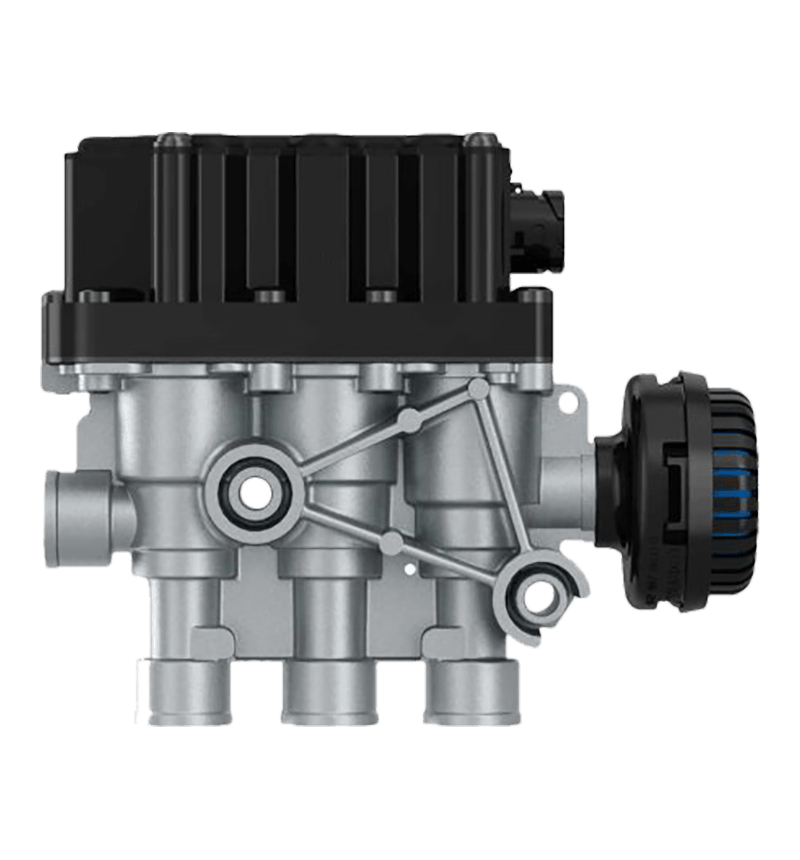

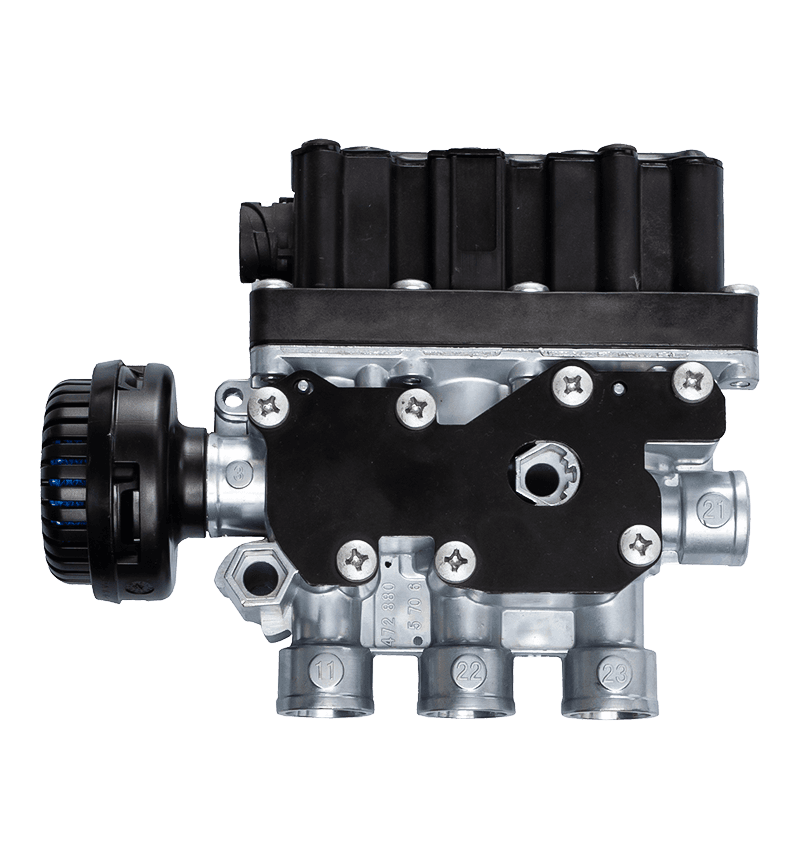

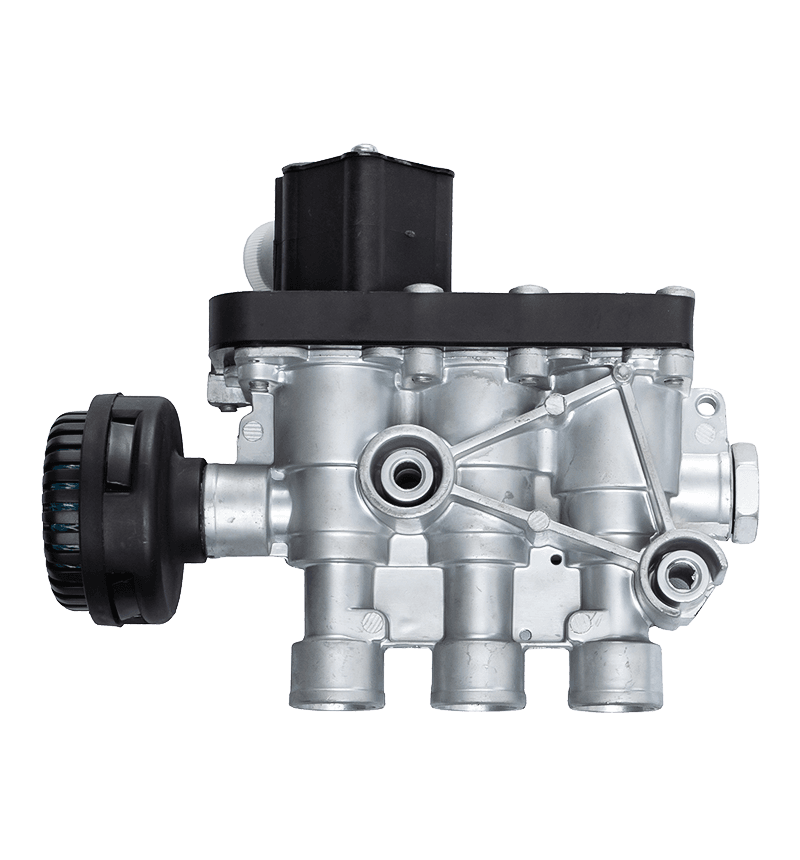

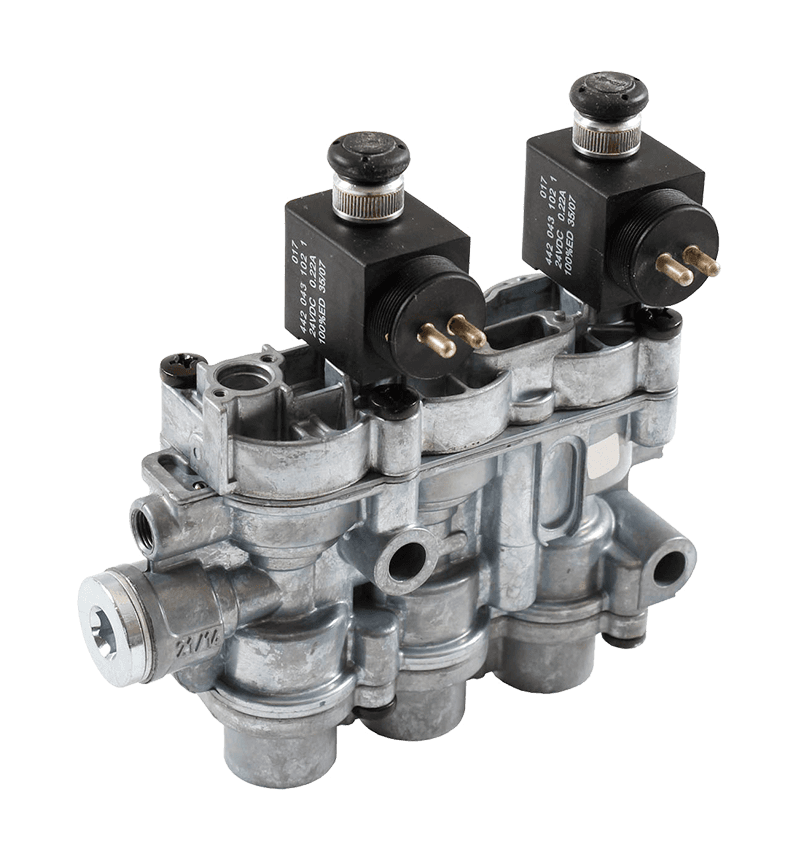

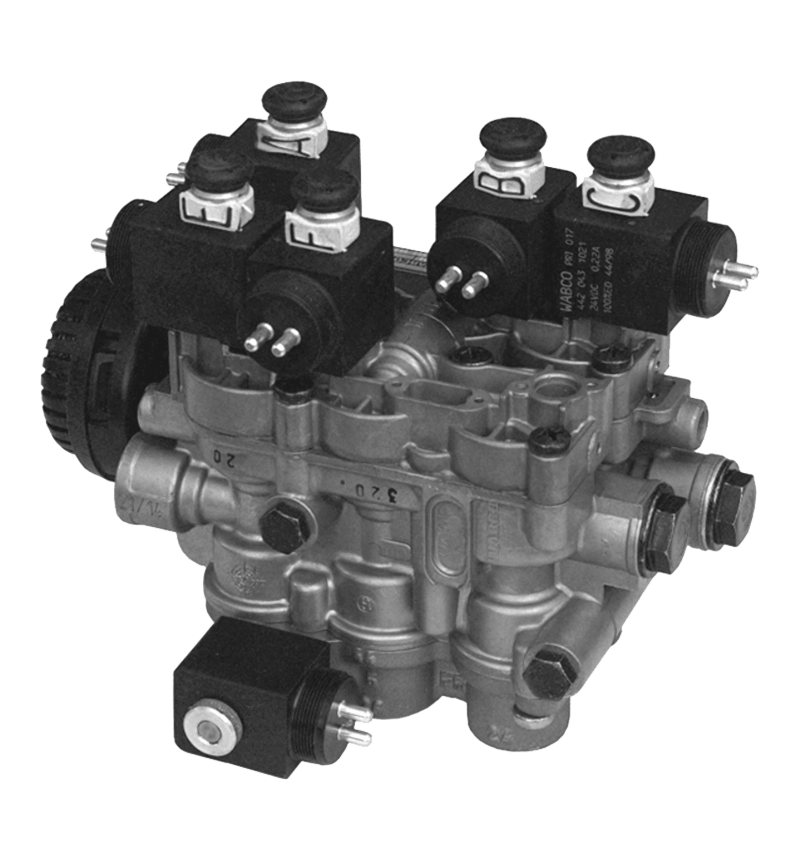

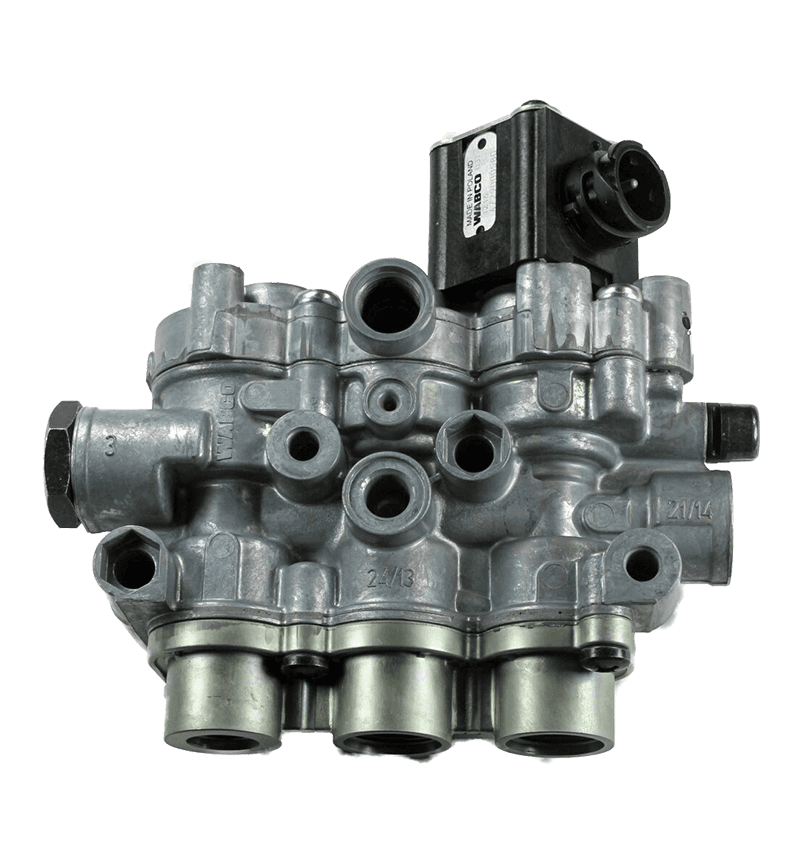

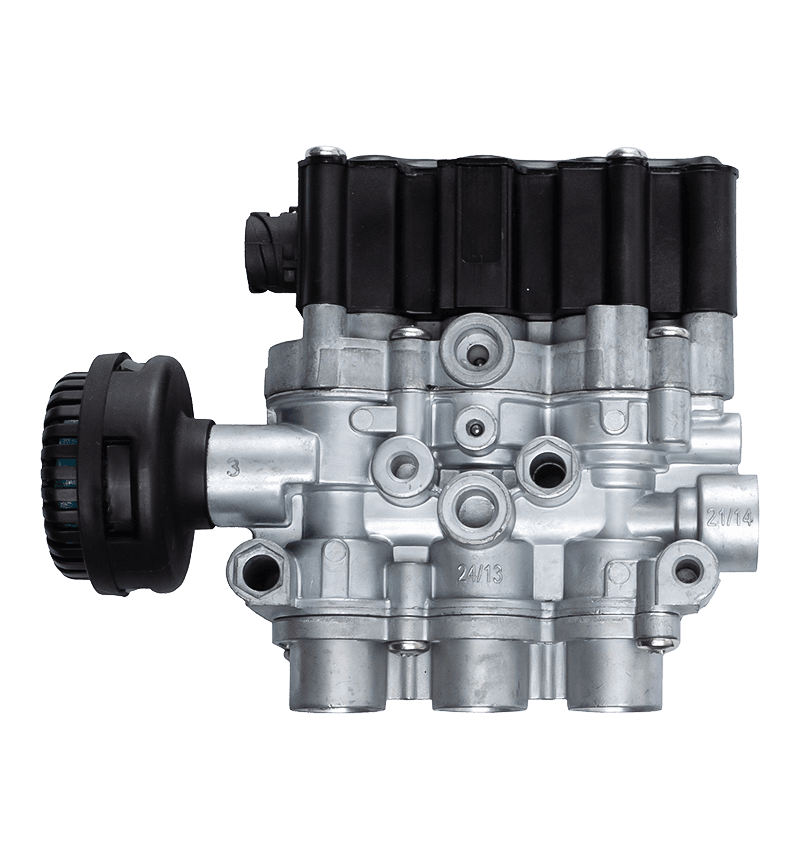

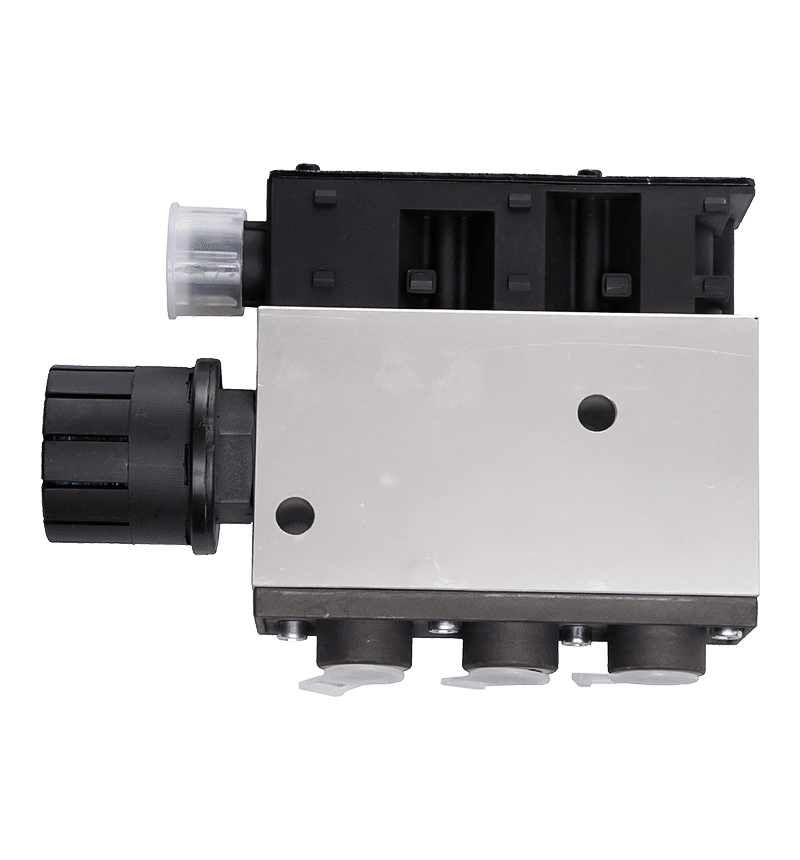

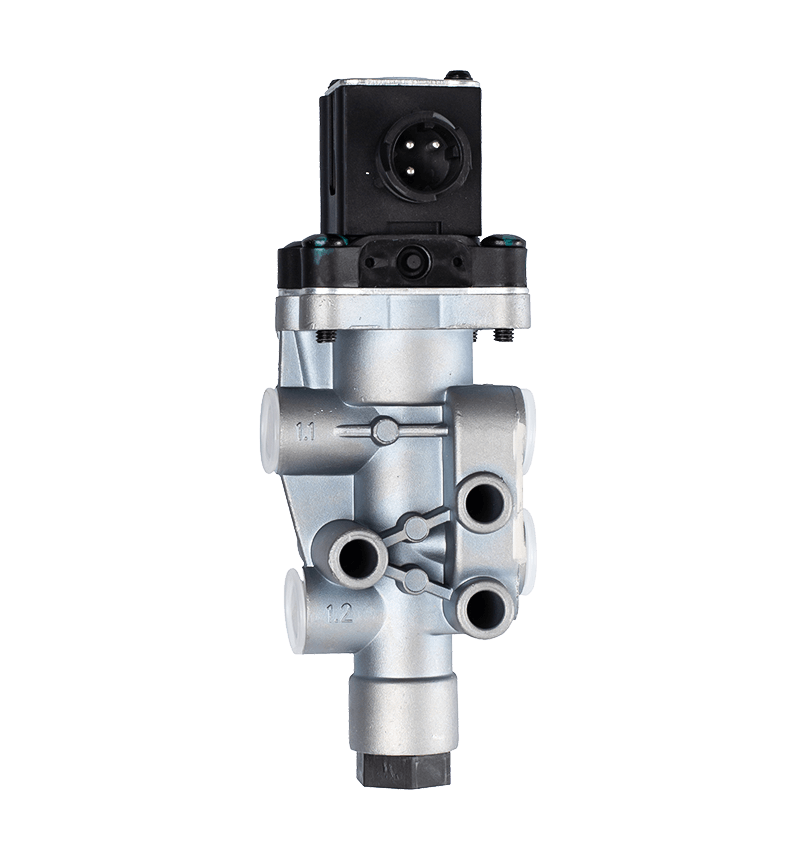

Servo mechanism, a physical execution unit, responds quickly after receiving the ECU's instructions, and generates corresponding power through its internal efficient mechanical structure. This power is transmitted and amplified by finely designed transmission devices - such as levers, gears, etc., and finally acts on the clutch system to help the clutch achieve fast and smooth engagement or separation.

Clutch Servo is designed with safety and reliability in mind. It is equipped with comprehensive safety mechanisms, such as overload protection and pressure limiting valves, to prevent potential safety hazards caused by system failure or improper operation. In addition, in order to facilitate drivers to make personalized adjustments based on their personal habits, Clutch Servo is also equipped with an adjustment mechanism that allows drivers to fine-tune the power assist as needed to achieve optimal driving comfort and convenience.

English

English Español

Español