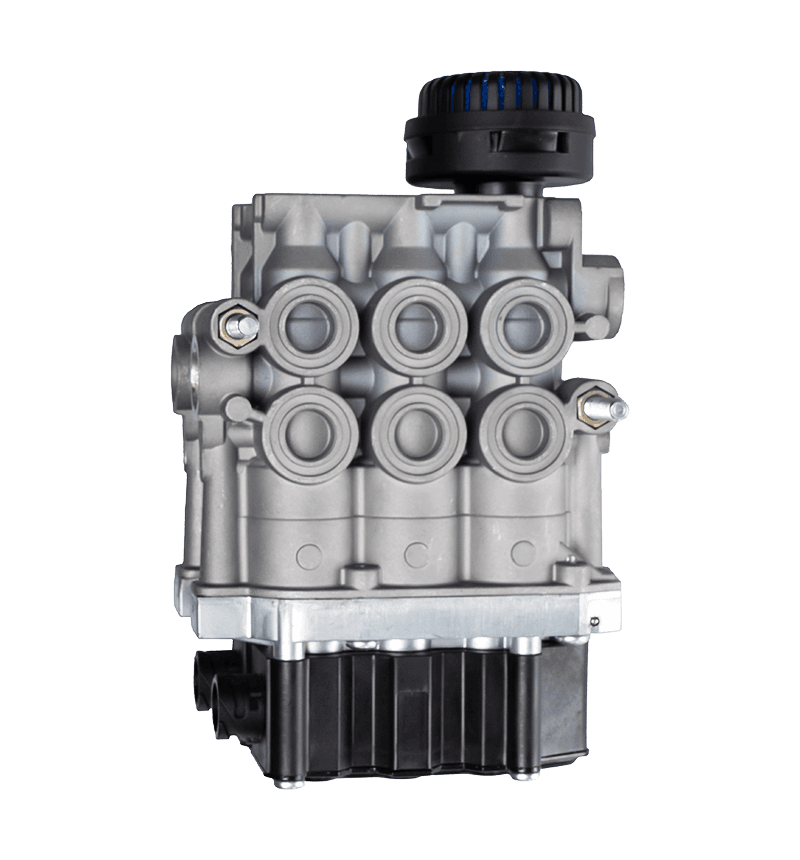

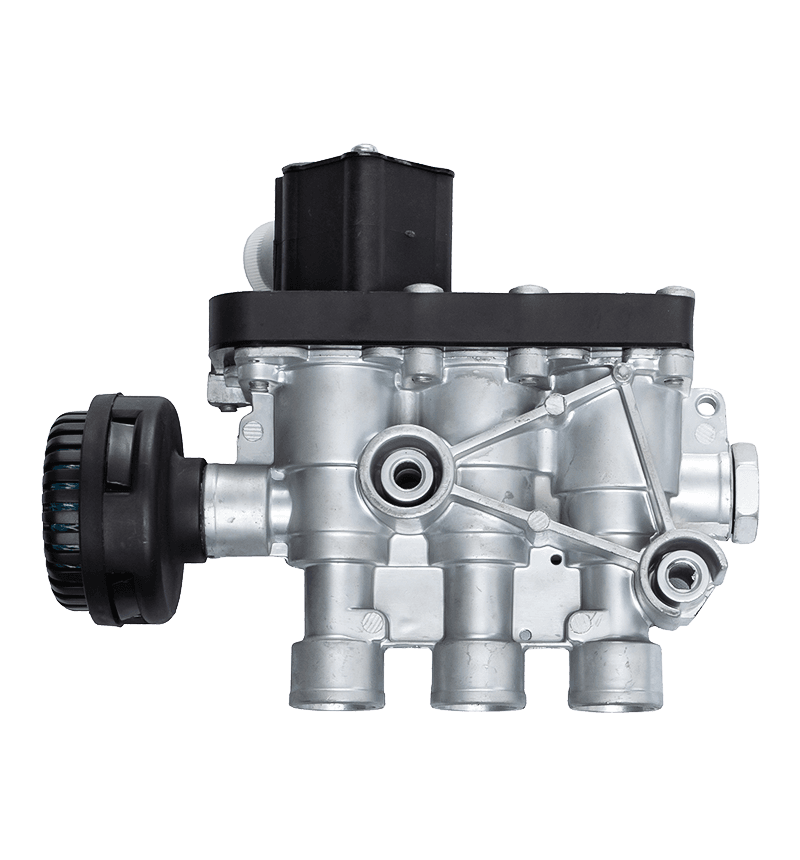

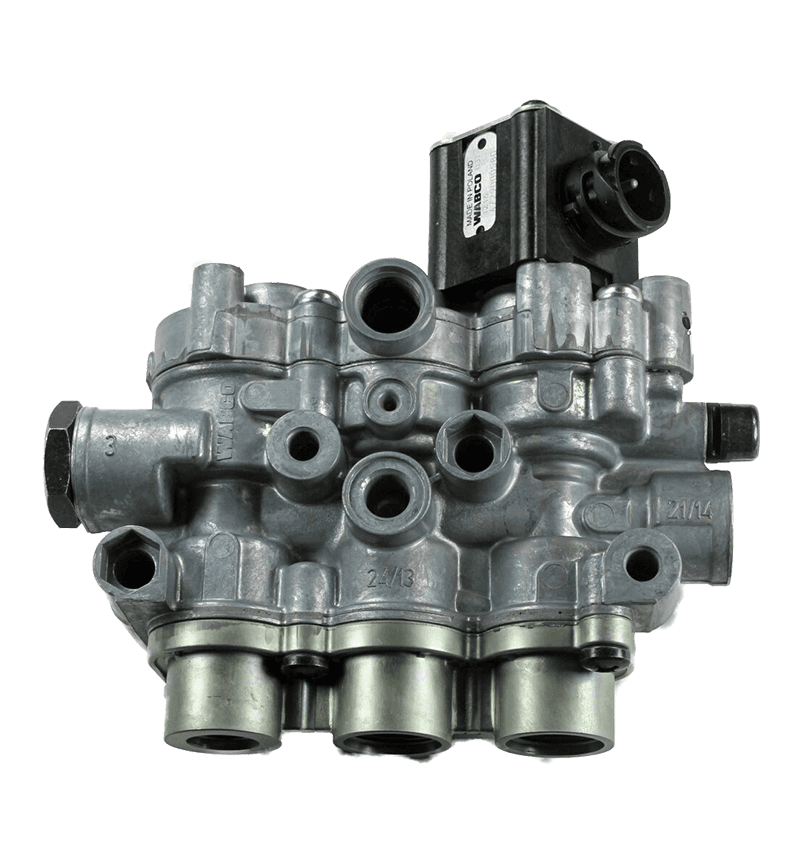

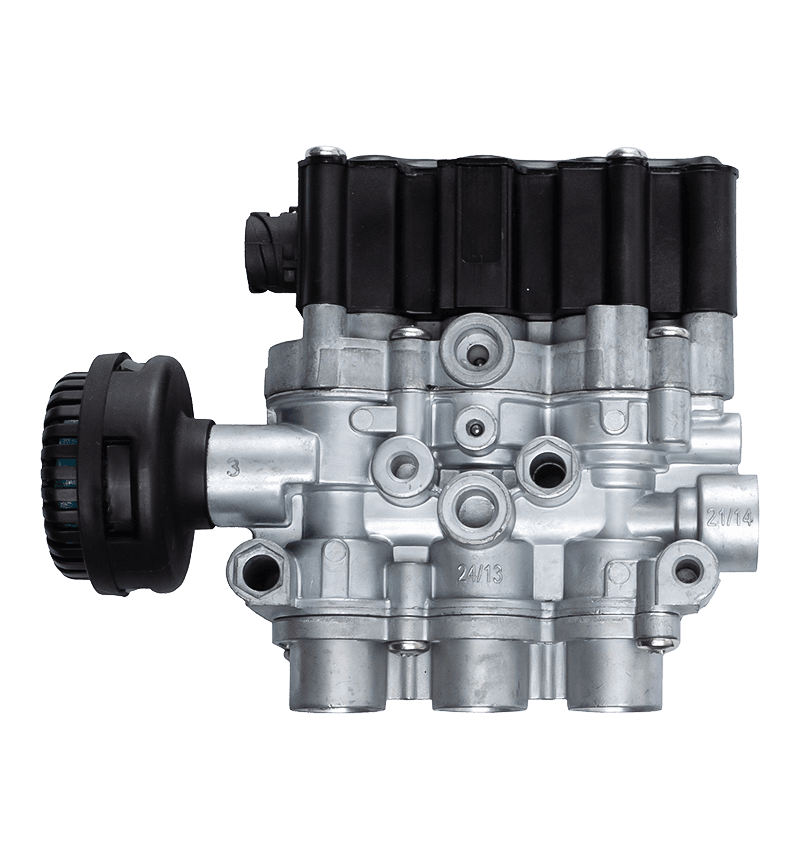

As a key component in the field of industrial automation and fluid control, the performance of leveling valves is related to the stable operation and efficiency of the entire system. As the heart of the leveling valve, the efficient actuator has become the focus of industry attention with its fast response capability

The importance of efficient actuators

In complex and changing industrial environments, the system's requirements for control accuracy are increasing. As an important tool for regulating fluid flow, pressure and maintaining system balance, the performance of the actuator of the leveling valve is crucial. The efficient actuator can respond to system instructions quickly and accurately, adjust the valve opening, and ensure that the fluid flows according to the preset parameters, thereby maintaining the efficient and stable operation of the system。

Working principle

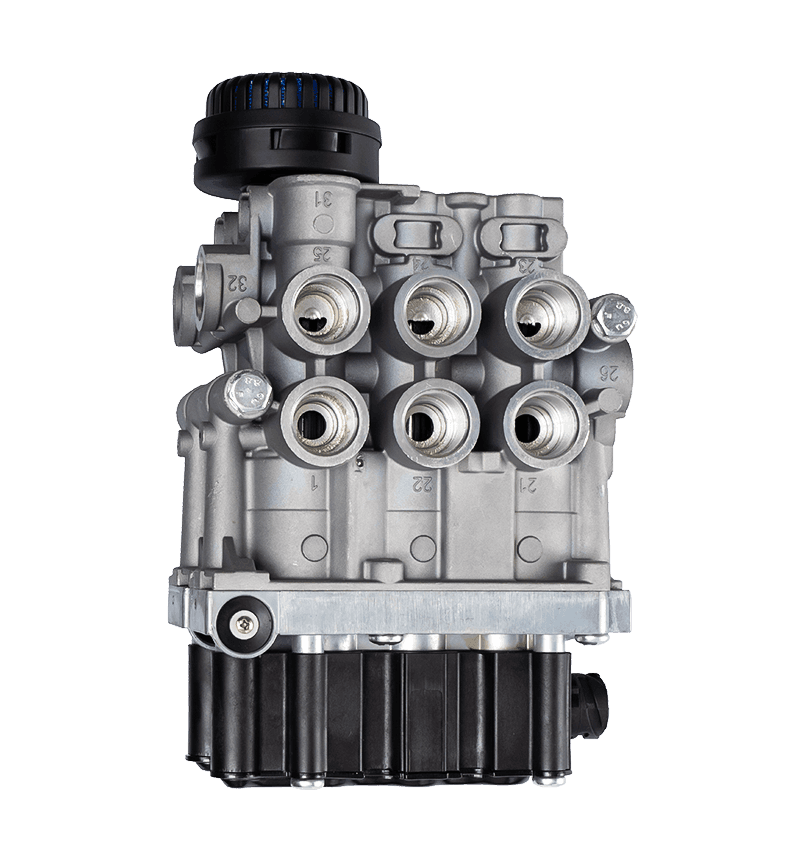

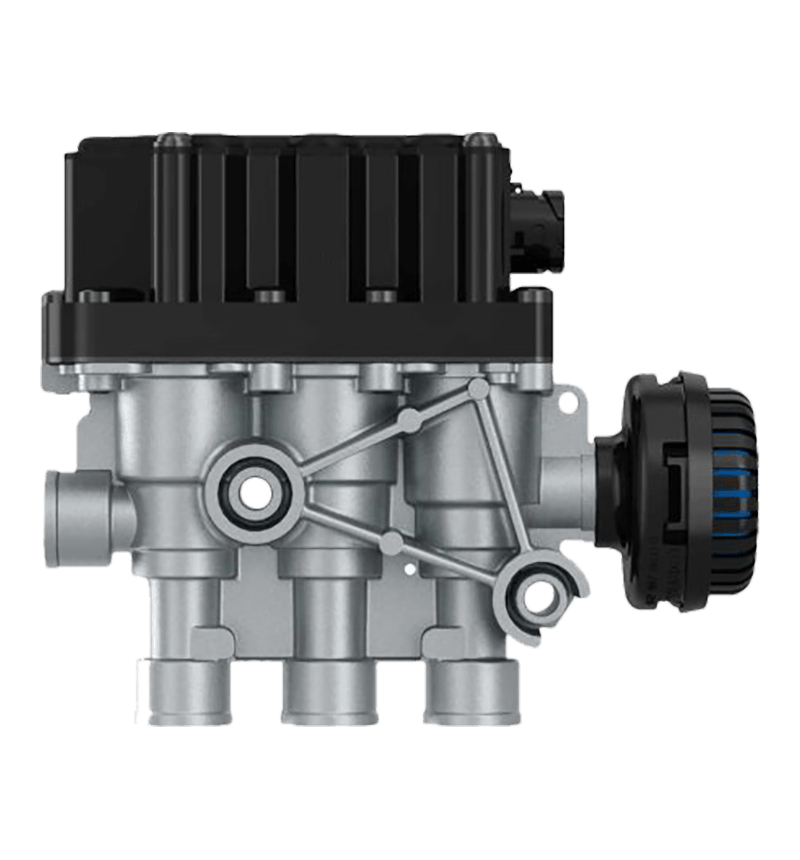

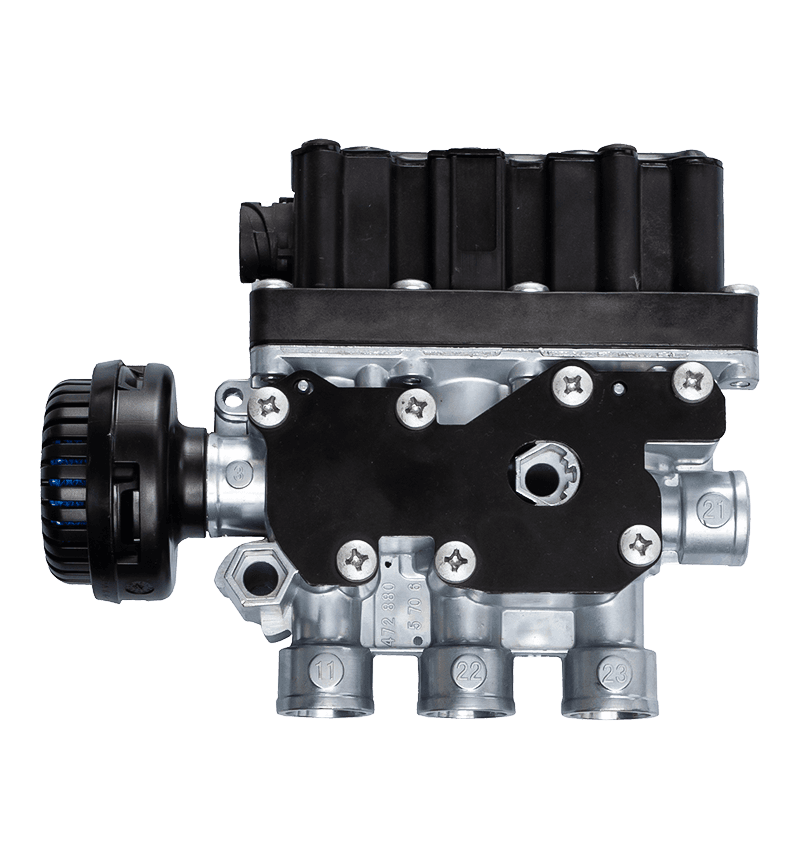

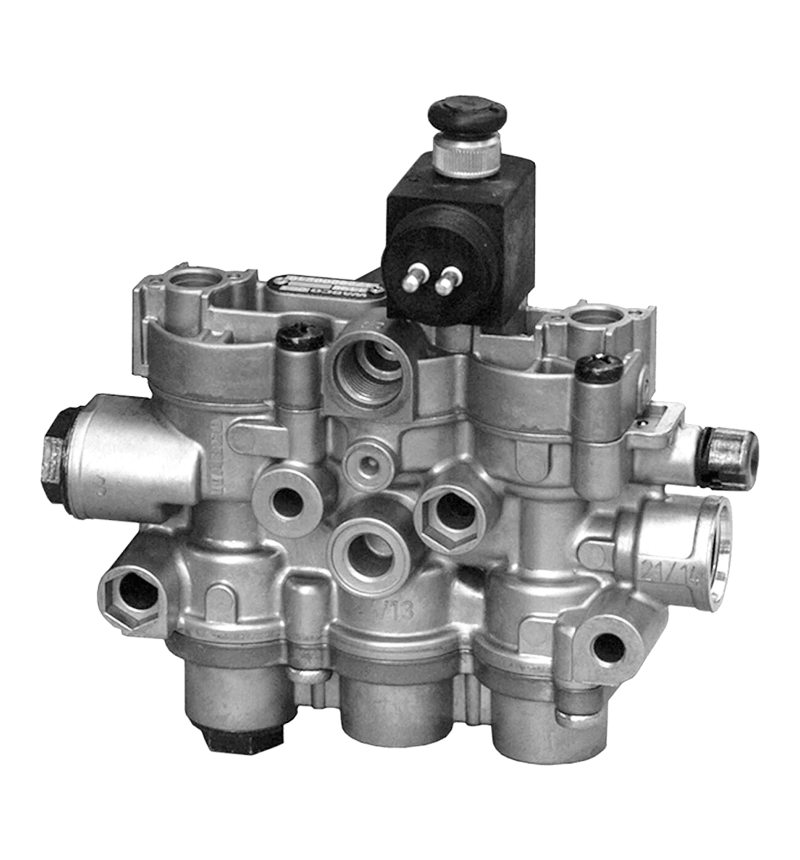

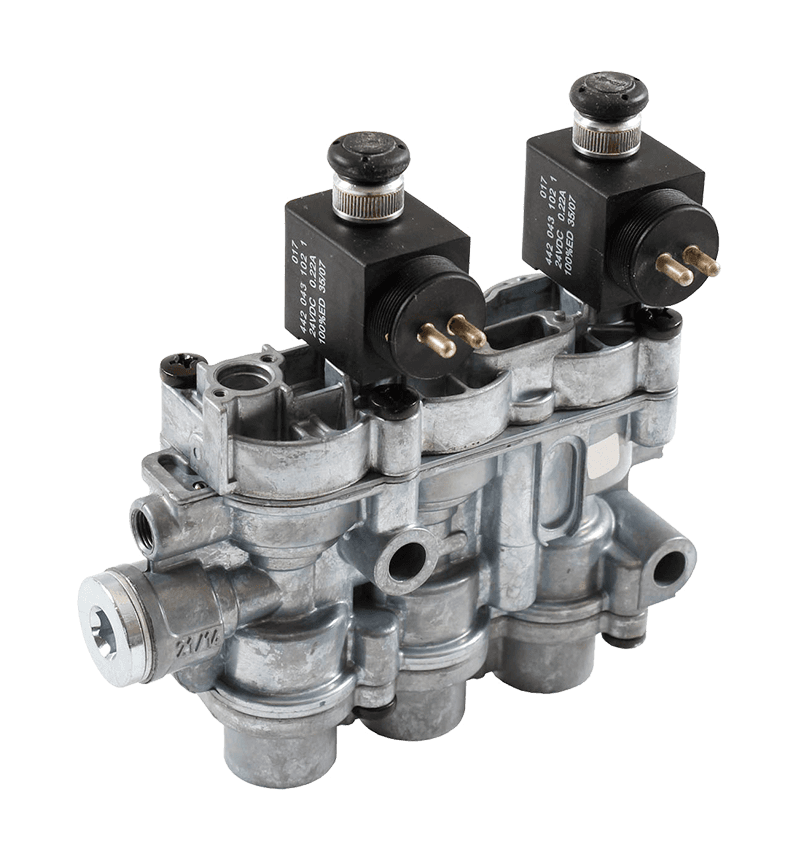

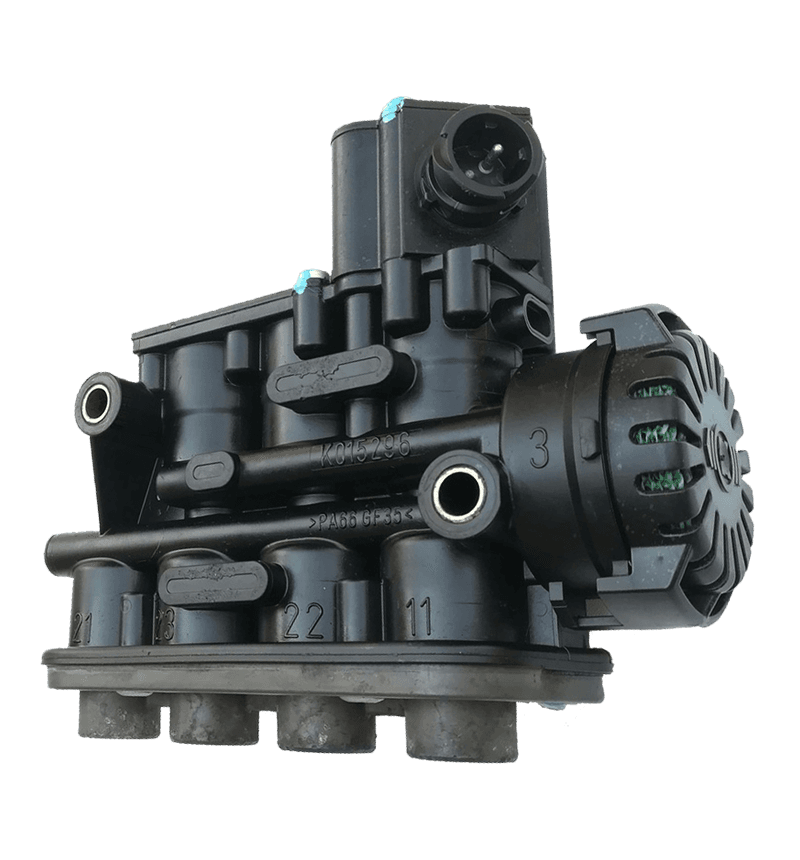

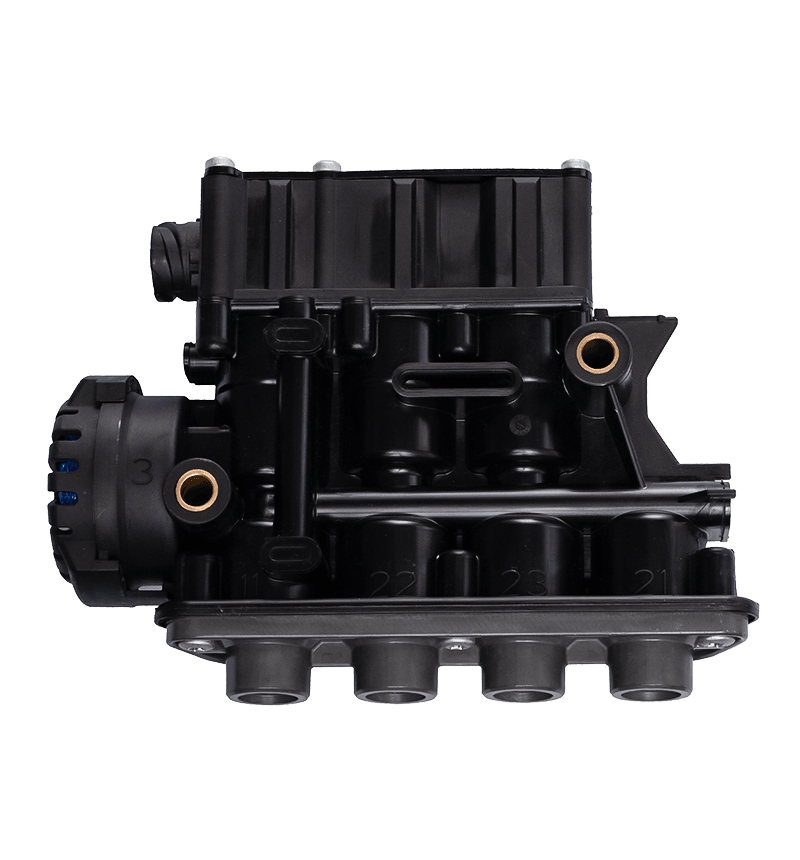

The efficient actuator usually includes core components such as motors, reducers, transmission devices and position feedback systems. When the system issues an adjustment command, the motor starts quickly, reduces the speed and increases the torque through the reducer, and drives the transmission device (such as gears, screws, etc.) to rotate. The transmission device is connected to the valve stem, driving the valve opening to change. At the same time, the position feedback system monitors the valve position in real time, and feeds back the actual position information to the control system to form a closed-loop control to ensure the adjustment accuracy.

Technical advantages

Quick response: high-performance motors and precision reducers are used to achieve fast start-up and precise positioning, ensuring that the valve can reach the specified opening in a short time.

High precision: combined with the position feedback system and advanced control algorithm, the valve opening can be accurately controlled to meet the high-precision adjustment requirements under complex working conditions.

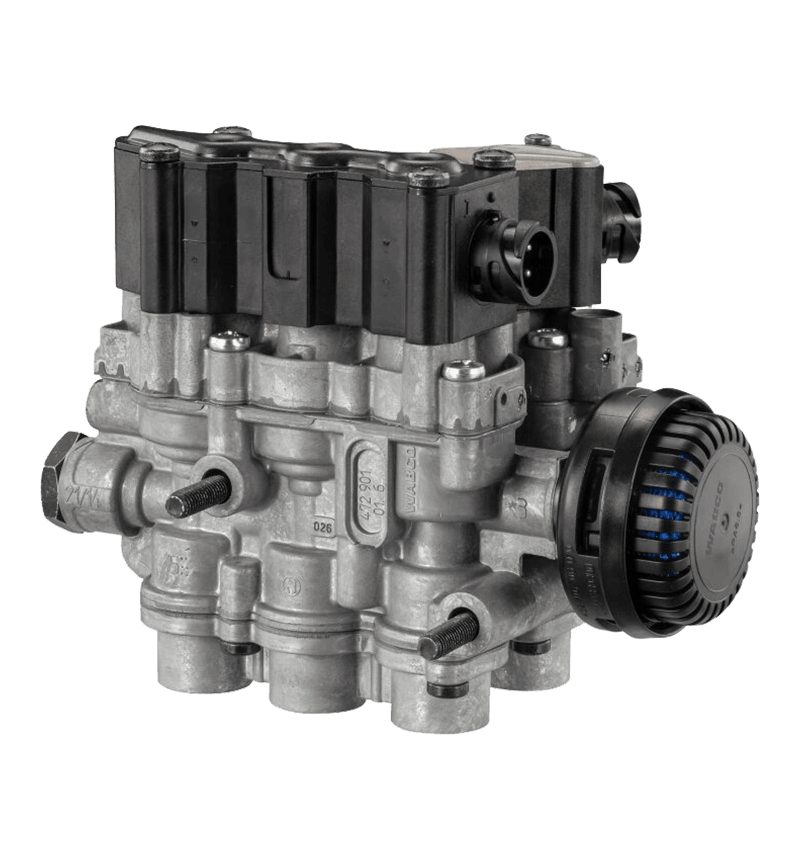

Good stability: optimize the transmission design, reduce friction and wear, and improve the reliability and service life of the actuator. Closed-loop control ensures stable operation of the system and reduces fluctuations and failures.

Intelligence: integrated intelligent control module, supports remote monitoring, fault diagnosis and automatic adjustment, etc., to improve the intelligence level and maintenance efficiency of the system.

English

English Español

Español